The ultimate battlefield between Tesla, CATL and BYD: solid-state batteries

- Get link

- X

- Other Apps

To what extent battery technology advances, the new energy revolution advances to which step.

For mobile phones, batteries are the kind that can celebrate the New Year without him. But for electric vehicles and photovoltaics, it is a fatal constraint, the one that cannot be bypassed at all. It can be said that the anxiety about batteries and the restriction of backward battery technology to various frontier applications are the biggest obstacles to the new energy revolution.

To what extent the battery technology advances, the new energy revolution will advance to which step, Belden will be the first driving force of the future new energy revolution.

01Why must it be a solid-state battery?

For electric vehicles to replace fuel vehicles, two fundamental breakthroughs must be achieved. The first is to get rid of dependence on subsidies, and the second is to tie fuel vehicles economically.

China’s subsidies for new energy vehicles are expected to withdraw in the last two years. At present, the first half of the battle is over. Under the leadership of Tesla (NASDAQ:TSLA), major manufacturers are basically ready for weaning.

The core economic problem in the second half surfaced, that is, the anxiety of restricting the mileage of electric cranes and fuel vehicles. And this problem, in the final analysis, lies in the battery.

Let's take the two mainstream electric vehicles in the current market as an example to see where the problem lies.

These are two new cars launched this year, one is the leading domestic electric car, BYD’s Han EV, and the other is the world’s leading electric car, Tesla’s model 3.

First, let everyone popularize a few general concepts. We know that a general household passenger car usually has a fuel tank capacity of about 55L. According to the fuel consumption of 8L per 100 kilometers, it can run about 600 kilometers. In order to achieve a seamless replacement of fuel vehicles, electric vehicle manufacturers have a basic goal of running 600 kilometers with a single charge.

In order to achieve this 600-kilometer cruising range, electric vehicle manufacturers must work hard on batteries.

In theory, you can stack enough batteries to achieve this goal, but we know that the batteries themselves also have weight and are not light, so manufacturers must find a balance between long mileage, vehicle weight and battery efficiency. This balance point is what we call the efficiency of battery packs.

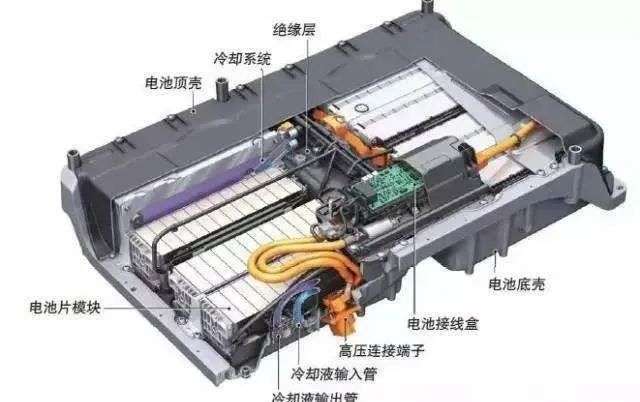

This is a diagram of a typical power battery system. It can be found that the cell module (that is, the battery cell we often call) only occupies a part of it. In addition, there are all kinds of miscellaneous accessories, such as cooling system, insulation layer, junction box, connection terminal and so on.

The core of the battery system capacity is the battery. The energy density of the battery is measured by wh/kg, which is how much energy can be produced per kilogram of the battery. Kwh is what we say in daily life, so the energy of the single battery The density of 170wh/kg means that every kilogram of battery cell can generate 0.17 degrees of energy.

We use the energy density of the battery system to measure the actual energy efficiency of an electric car. In addition to the battery cells, the battery management system, thermal management system, high and low voltage circuits contained in the battery system occupy part of the weight and internal space of the battery system, so the energy density of the battery system is lower than that of the single battery cell. .

The ratio of the energy density of a battery system to the energy density of a single cell is the efficiency of the battery pack, which is a core indicator of the efficiency of a battery system.

For example, our two cars above:

BYD’s Han EV has a battery cell energy density of 170wh/kg. After the battery pack is formed, the battery’s system energy density drops to 140wh/kg, and the group efficiency is 82.53%; Tesla’s latest model 3 long battery life version, battery cells Using Panasonic's 21700 battery, the cell energy density is nearly double that of the lithium iron phosphate blade battery used in BYD Han EV.

However, the ternary lithium battery selected by Tesla is easier to generate heat than BYD's blade battery, requires more heat dissipation equipment, and the battery management system is more complicated. Therefore, the energy density of the combined battery system quickly drops to 161wh/ kg, the group efficiency is only 53.67%.

These two models represent the current mainstream configuration of electric vehicles, and the main indicators are very close.

Their cruising range is more than 600 kilometers, the total power is about 77kwh, which is 77 kilowatt-hours of electricity, and the battery system is very heavy. The BYD Han EV549kg is more than half a ton, and the Tesla model 3 long-range version is 477kg, which basically accounts for the whole A quarter of the weight of the car. Whether from the perspective of energy saving or tapping potential, battery technology must have major innovations.

So how much improvement does the power battery technology need to make to truly set the threshold for replacing fuel vehicles?

At present, the accepted answer in the market is that the energy density of the battery system of existing electric vehicles has doubled and a half, from the common 160wh/kg to 400wh/kg, which is the beginning of the complete replacement of fuel vehicles by electric vehicles. This indicator means a battery life of 600km, an electricity of 80 degrees, and a total weight of about 200kg. Now the weight is about 450-550kg.

400wh/kg is a very rigid indicator. When a product is finally promoted, the survival of the fittest must be achieved. The core is cost. No matter how much the ideal and the future are, it is not cheaper than the reality. If an electric vehicle fails the cost-effective line, it will always be It is a niche toy.

If you go to the 400wh/kg indicator, you will find that the current power battery market is far from being able to speak of a clear competitive landscape, and everyone is basically on the same starting line.

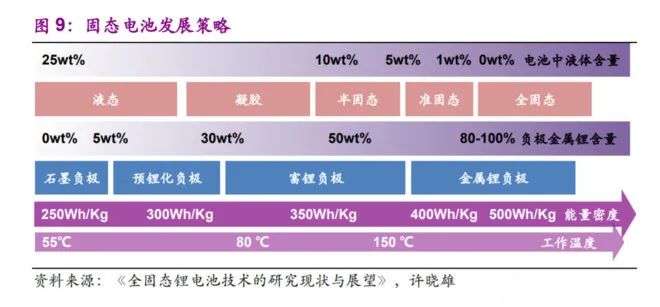

The above picture is a picture taken from Everbright's report "Solid State Batteries: Seizing the Commanding Heights of Next Generation Lithium Battery Technology", which outlines the current battery technology development path.

No matter what kind of solution you are, the highest theoretical energy density is the sky. The talent is so, no matter how hard you work, it is useless.

Our current mainstream batteries, whether they are lithium iron phosphate batteries or ternary lithium-ion batteries, are lithium-ion batteries with liquid electrolyte. The theoretical maximum energy density is 350wh/kg. If you add various battery management systems, Being able to achieve 300wh/kg for the whole system is basically the limit.

This is like you have achieved the ultimate in bow and arrow, and in the end you are killed by a musket. Without him, this is the crush of generations.

Therefore, the final solution to the problem of battery energy density and eliminate mileage anxiety must be solid-state batteries.

Solid-state batteries are still on the way to research and development. So can we achieve this indicator?

can. Engels said, "Once society has technical needs, this need will push science forward more than ten universities." Demand is the best motivation. Compared with fuel vehicles, electric vehicles have more space and potential.

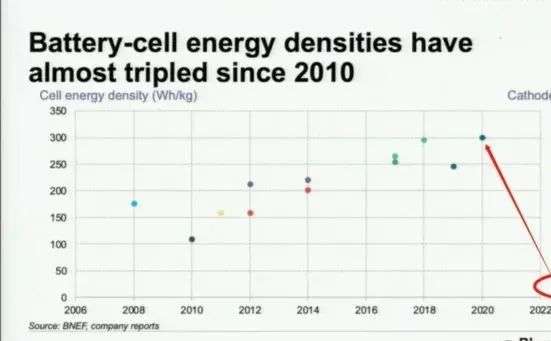

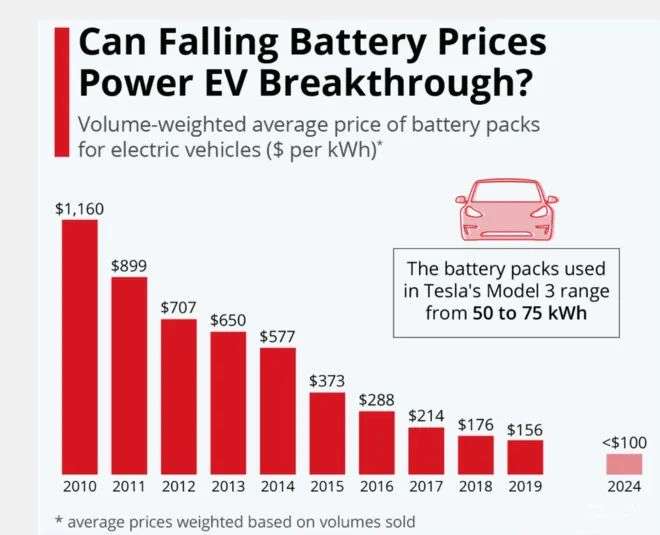

We look at the battery field, what has happened in the past 10 years.

According to BloombergNEF data, in the past 10 years, the energy density of batteries has basically tripled. This also shows how fast the industry is progressing, driven by strong demand.

A few months ago, Tesla dropped the entry version of Model 3 from 291,800 yuan to 249,900 yuan, a drop of more than 40,000. We are optimistic about the process of replacing fuel vehicles with electric vehicles, but this entry-level model uses a lithium iron phosphate battery from the Ningde era. The energy density of the battery system will not be much better than that of BYD's blade battery, which is about 140-160wh/kg.

Compared with the ternary lithium battery configuration of the original product before the price cut, the battery safety of model 3 has been slightly improved, but the system energy density has dropped, which has an impact on the existing electric vehicle manufacturers BYD, Xiaopeng, etc. Will explore the traditional B-class cars Passat, Accord, and Camry markets, which will suppress them to a certain extent.

But in general, if the energy density of the battery system is not greatly improved, and the threshold of 400wh/kg cannot be exceeded, it is still a tactical improvement, and there will not be much change in the pattern.

02 The second constraint of photovoltaics

We know that the photovoltaic industry follows Moore's Law, and the annual power generation cost will decrease proportionally. In 2020, parity has been achieved, that is, the price will be equal to that of coal power, and the subsequent power generation cost will continue to fall. The ultimate limit is that the energy price is close to zero.

To use the term "dumb bullshit", if photovoltaics want to achieve a flat push on traditional energy, they must break through two restrictions: one is to get rid of subsidy constraints, this one is basically achieved with parity online, and the second is to get rid of grid connection. Constraints, this is to be realized in the future.

Photovoltaic, as a new form of energy, has its advantages visible to the naked eye. Energy-saving and environmentally-friendly resources are renewable and inexhaustible. So at the beginning, various countries have given a lot of subsidies, but such subsidies are not a long-term solution.

The wool comes from the sheep, and the cost of new energy still needs to be borne by the whole society. If it cannot get rid of the constraints of such subsidies, photovoltaics can only be used as a fashion and occasionally appear on the performance report as an embellishment.

To get rid of subsidies, the price of photovoltaics must drop enough to compete with traditional energy sources. With the rapid iteration of Chinese manufacturing in photovoltaic technology, the cost has dropped rapidly. Finally, by 2020, the cost is close to that of coal power, and it can get rid of subsidies and go online directly. So the first constraint is solved.

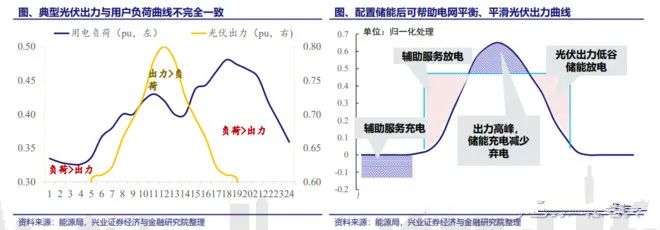

But if the second constraint, that is, the grid connection constraint cannot be broken, the promotion of photovoltaics must still be restricted within a certain range. why? This is determined by the characteristics of photovoltaic power generation.

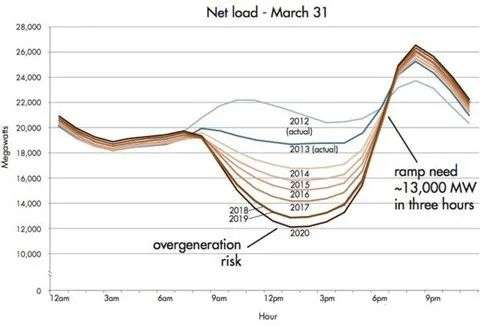

The picture above is the famous duck curve, which shows the net electricity load in California, USA on March 31st each year. In California, we know that the sun is shining, the scenery is beautiful, and the sunshine time is long. It is especially suitable for photovoltaic power generation. In addition, it is also located in Silicon Valley, and the acceptance of new energy is high. The proportion of photovoltaic power generation is close to 30%.

During the day, the sun is the strongest at noon, but not much electricity is used, so the grid load is the lowest. At night, when the photovoltaic power is off, the electricity consumption soars and the grid load also jumps rapidly. This is the long line in the figure. Duck neck.

Due to China’s entry, the price of solar modules has been declining year by year, and the proportion of photovoltaic power generation in California has also become higher. Since 2012, the duck belly with the net load of electricity has also become bigger and bigger, and the whole is like a duck. , So called the duck curve.

This curve reflects the second constraint faced by photovoltaic power generation, grid-connected power generation. After all, photovoltaic power generation is constrained by natural conditions. When there is sun during the day, the power generation will be more, and it will stop at night, but our electricity consumption is the other way around.

To solve this problem, we are now adopting the method of peak shaving of coal power or natural gas power generation to compensate. These peak shaving units are shut down during the day and only start up at night.

This involves a problem of the grid consumption ratio. The entire grid system, the proportion of photovoltaic power generation has a limit, this upper limit is basically about 30%-40%, depending on the grid peaking level and daily light conditions .

So can we completely break through this constraint? can.

This picture comes from a report by Zhu Yue, a researcher at Industrial Securities Power Equipment: "Growth Edge, China Power". If photovoltaic power generation wants to break through the 30%-40% upper limit, it needs to be equipped with energy storage facilities to store electricity during the peak power generation period at noon, and release the electricity during the peak power consumption period at night, so that coal and Natural gas, only photovoltaics are used to meet the needs of the entire power grid around the clock.

In order to break through the second constraint, photovoltaic power generation needs to achieve that the system cost of photovoltaic + energy storage power generation after energy storage facilities is lower than the existing coal power generation, in order to get rid of grid connection constraints and truly enter the philosophical "kingdom of freedom" "Changing the power grid will also completely change the world.

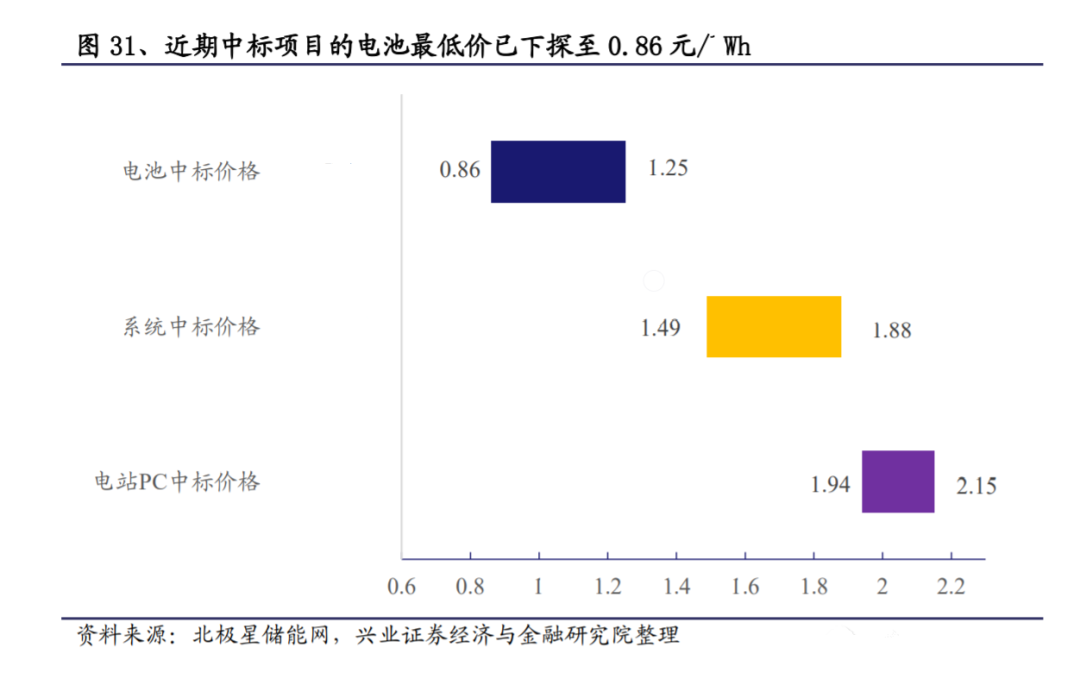

The core requirement of photovoltaic grid-connected energy storage is that the absolute price is low enough, and this price refers to the full cost. Let's look at the quotations of the winning bids for photovoltaic energy storage power stations compiled by Industrial Securities, as shown in the following figure:

Now the lowest winning bid price of photovoltaic energy storage battery is 0.86 yuan/wh, plus the battery management system (BMS), the lowest winning bid price of the battery system after the inverter (PCS) is 1.49 yuan/wh, including civil engineering and system integration For the full photovoltaic energy storage power station, the minimum is 1.94 yuan/wh.

And this 1.94 yuan is the full cost of photovoltaic energy storage. 1.94 yuan/wh, once a kilowatt-hour of electricity is kwh, converted into a kilowatt-hour construction cost is 1940 yuan/kwh, assuming that 10,000 charge and discharge cycles can be achieved, regardless of the capital cost, the cost of energy storage per kilowatt-hour is 0.194 yuan .

But in fact, it is difficult for our existing energy storage power stations to achieve a charge-discharge cycle life of 10,000 cycles, generally around 5,000 cycles. The cost per kilowatt-hour of electricity is nearly 0.4 yuan, which is about In the long run, the price of existing thermal power needs to have room to drop.

So what price does the cost of energy storage need to drop to achieve a breakthrough? At present, the general consensus in the market is that the cycle life is 10,000 times and the total construction cost is 1 yuan/wh.

According to this indicator, the cost of energy storage per kilowatt-hour is 0.1 yuan. At this price, the energy storage power station can survive without any subsidies or the peak-to-valley price difference. At this price, the cost of photovoltaic power generation needs to be reduced from 0.4 yuan/kwh to 0.3 yuan/kwh. In this way, the cost per kilowatt-hour of photovoltaic + energy storage will be 0.3+0.1=0.4 yuan/kwh, and the price will be approximately equal to the existing coal-fired power, thus completely getting rid of grid connection constraints.

Is there room for the cost of energy storage to continue to fall? Yes, and it may drop faster than the power battery.

First of all, because the price of power batteries has dropped rapidly, and energy storage batteries can fully learn from the technology of power batteries, in fact, many photovoltaic energy storage devices directly use second-hand car power batteries. As shown in the BloombergNEF data above, the power battery has dropped from US$1,160 per kilowatt hour in 2010 to US$156 in 2019. In 9 years, the price has dropped by nearly 87%.

Secondly, the battery required for photovoltaic energy storage is lower than that of the power battery, and the range of options is wide. Relative to the extreme pursuit of power batteries for weight, volume, price and efficiency, photovoltaic energy storage batteries only need to meet a long enough cycle life and low cost per kilowatt-hour. The requirements for power batteries are small in size and light, and energy storage power stations are not strict. Therefore, the greater the range of options, the greater the probability of achieving technological breakthroughs.

The photovoltaic industry has its own Moore's Law, that is, for every doubling of power generation capacity, the price of newly installed electricity is reduced by 16%. From the perspective of energy storage technology, with the advancement of battery technology, each time the total capacity of photovoltaic energy storage doubles, the cost of a single charge and discharge cycle will also decrease in a certain proportion. In the next ten years, we will most likely see a rapid decline in the cost of energy storage.

03 Leading the way for three to five years

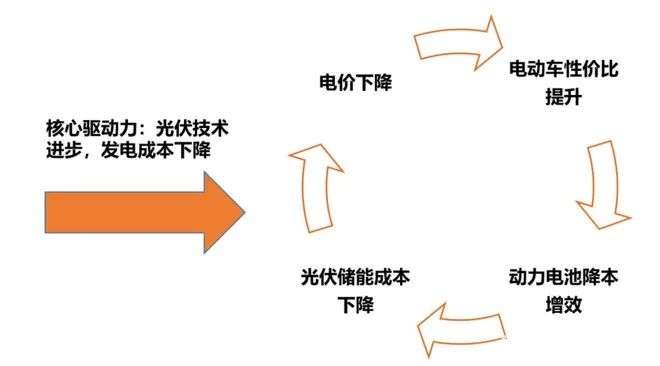

Later we will see a process of mutual promotion of a spiral, and the demand for batteries will show an exponential growth.

According to Newton’s first law, “any object must maintain a uniform linear motion or a static state until the external force forces it to change the state of motion.” In this cycle, the external force or the first driving force is the photovoltaic technology brought about by the advancement of photovoltaic technology. The rapid decline in power generation costs.

Photovoltaic power generation costs are falling rapidly, forcing electricity prices to decrease steadily, power demand is increasing, and the cost-effectiveness of electric vehicles continues to increase, forcing power batteries to improve, power batteries are reduced in cost and efficiency, energy storage batteries are cost-effective, and various application scenarios have entered the break-even point. , Which has increased the demand for electricity. This is a positive and complete cycle.

As an investor, the most desired scenario is of course the rise in volume and price. I have seen many power equipment researchers who are talking about the logic of electricity price increases, and have made very optimistic estimates of future electricity prices and subsidies, but this assumption In essence, they are untenable, and we do not approve of it.

Because the core of large-scale industrial production is to reduce costs and improve efficiency. Under the scale effect, costs are lowered, prices are lowered, and profits are thin, but the cake spreads are large.

In industry, any logic that talks about long-term price increases is flawed. For example, we have doubts about the long-term growth of resource-based companies such as Ganfeng Lithium (SZ:002460), because raw materials must not be a constraint if an industry wants long-term sustainable growth. Why the semiconductor industry has grown bigger on the basis of silicon is because sand is everywhere and there is no possibility of scarcity.

We have spent so much time thinking about the path of the energy revolution in the future, but predictions belong to predictions, and investment belongs to investment. Even if you see the right direction, you may not necessarily choose the right stocks. If you choose the right stocks, you may not be able to complete it. .

Indeed, the new energy revolution brought about by photovoltaics will completely change this society, but this high-tech industry, according to E Fund’s fund manager Xiao Nan, has a very unfriendly business model.

This business model belongs to "self-burning, burning oneself, illuminating others. Such companies are very tired, they have to spend a lot of money to invest in fixed assets, to invest in research and development, they give all the efficiency saved to their customers , Because if you don’t do this, you will face elimination and be abandoned by customers."

The competition in the direction of new technology is extremely cruel, and it is often three to five years that each leads the way.

- Get link

- X

- Other Apps

Comments

Post a Comment