To realize the "freedom of electric vehicle endurance", is it really necessary to rely on long endurance?

- Get link

- X

- Other Apps

Compared with the ever-increasing cruising range on the dashboard, the unreality of cruising seems to be another anxiety for car owners.

In recent years, the cruising range of electric vehicles has been greatly improved. From lightweight body design to overall manufacturing process upgrades, car companies have maximized the cruising performance, which to a certain extent alleviated the mileage anxiety of new energy vehicles . On the other hand, car owners found that the battery life did not meet expectations after using the car.

The same as the fuel consumption of fuel vehicles under "comprehensive operating conditions", due to the deviation of the test method from the actual driving environment, it is difficult for new energy vehicles to reach the endurance scores calibrated by the manufacturers. The actual cruising range has a lot to do with driving style and outdoor temperature. From the design of the body structure to the power of on-board electrical appliances, every design will affect the actual endurance performance.

Picture source network

The three-electric system is a key indicator of new energy vehicles. The battery energy density, motor performance, and the performance of the electric system will directly determine whether the battery life is excellent. If car companies take the lead in the three-electric field, they can outperform the next round.

With the continuous popularization of new energy vehicles, there are more and more "high endurance" models, but the actual endurance that does not match the publicity has become a new "mileage anxiety", and the call for "endurance" is getting higher and higher.

01Who can achieve "true battery life"?

When promoting new energy vehicles, it has become a tacit fact to select the "best" results in the test.

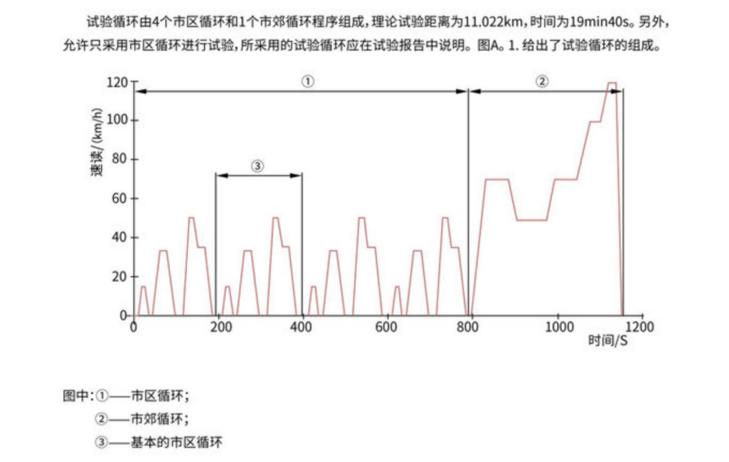

At present, most car companies have adopted NEDC (New European Driving Cycle) European endurance test conditions. The test consists of 4 urban cycles and 1 suburban cycle. The maximum speed of the urban cycle is 50km/h and the average speed is 19km. /h, the maximum speed of the suburban cycle is 120km/h, and the average speed is 62km/h. The simulated working condition test is cyclically performed in a relatively single test environment, maintaining the speed after accelerating, and then decelerating to stop.

Source: Yiche

However, the NEDC operating condition standard is derived from the testing of fuel vehicles. Although rigorous, it can no longer meet the current development of the new energy vehicle market. The straight acceleration and deceleration and constant speed curves are also quite different from the real driving conditions.

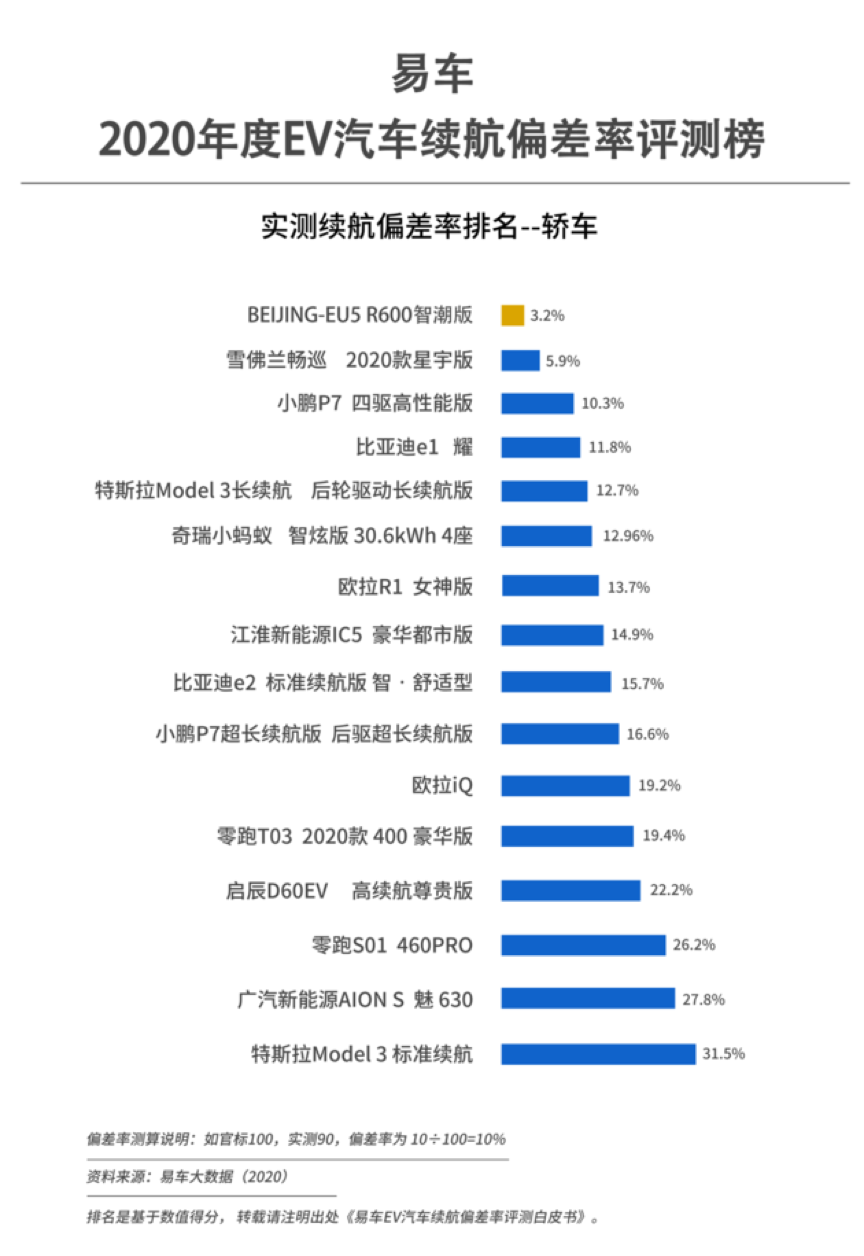

Not long ago, Bitauto, based on the WLTP evaluation standard, compared the actual range of new energy vehicles measured as of October 2020 with their NEDC operating conditions. If the official standard battery life is 100km and the actual measurement is 90km, then the deviation rate is 10%. The higher the deviation rate, the greater the measured battery life and the official standard battery life.

Unlike NEDC, the WLTP world light vehicle operating condition test procedure uses a more stringent and complex test method. By setting test procedures that can represent global urban roads, highways, mountain roads and other road conditions, and let vehicles drive strictly in accordance with fixed routes. The test time for each part is fixed, but the acceleration and speed curves are different, and the maximum vehicle speed is limited to further ensure the accuracy of the test.

WLTP also includes the rolling resistance, gear and weight of the vehicle as variable factors into the test range, so the endurance performance tested by the WLTP standard is closer to reality.

Source: Yiche

Unlike other brands of electric vehicles, BEIJING-EU5 has not shown any significant shrinkage under strict test standards. In the "BeiJing 2020 EV endurance deviation rate evaluation list", BEIJING-EU5 ranked first with a deviation rate of 3.2%.

This means that the actual cruising range of BEIJING-EU5 is the closest to its officially announced NEDC operating conditions. Many car companies worry about the shrinking of the cruising range and become the killer of BEIJING-EU5.

02 The core three-electric technology determines the leading advantage

The reason for the solid battery life of BEIJING-EU5 is its leading three-electric technology.

As the earliest domestic enterprise focusing on the R&D and manufacturing of pure electric vehicles, BEIJING Automobile has gradually accumulated domestic leading technological achievements in the fields of batteries, motors, and electronic control after years of practice and technical exploration.

EU5 Source: BEIJING Automobile Official

Take BEIJING-EU5 as an example. This model uses Ningde era high-performance ternary lithium battery, which has the advantages of high energy density and light weight. Its battery cell energy density is as high as 212Wh/kg, and the battery pack energy density is as high as 161kw/kg. It is equipped with a liquid-cooled temperature control system as standard and has a long battery life of 501km.

The reason why the battery life is not compromised is also due to its mature BMS battery management system. The system has the function of self-equalizing battery cell voltage deviation, which can intelligently monitor and adjust the battery cell voltage to extend battery life while ensuring that the vehicle maintains a long battery life.

BEIJING Automobile and CATL jointly launched the world's first CTP power battery system. PED increased by 20% to 160Wh/kg, leading the industry

The permanent magnet synchronous motor mounted on the vehicle is integrated with the motor, reducer, motor control and power conversion system, which can realize the platformization and modularization of the whole vehicle, with low energy consumption, and the peak efficiency is increased to 96.8%. The overall power performance is almost equal to 2.0T engine is equivalent.

BEIJING also has an intelligent electronic control system with completely independent intellectual property rights. The system monitors the data of 260 components of the whole vehicle in real time, so as to realize intelligent distribution of electric energy, intelligent management of power, and intelligent adjustment of driving control, which can make the energy efficiency conversion rate as high as 98.5% and greatly reduce the power consumption per 100 kilometers. Under the same power condition, It also makes battery life longer.

In addition, the FERT full-time full-power energy recovery technology can increase the vehicle's driving range by 0.5% through the efficient use of battery feedback power time characteristics. One-pedal single-pedal braking energy recovery maximizes the power utilization rate. While effectively improving the recovery effect when the brake is stepped on, it can also achieve 10% energy saving.

FERT, IRM, One-pedal, BPI work together to effectively reduce consumption and extend battery life

The core three-electric technology guarantees the endurance of "genuine products" and continues to push BEIJING cars forward. According to official data, up to now, the sales of BEIJING's new energy vehicles have exceeded 500,000, and the cumulative mileage has exceeded 16.6 billion kilometers. On October 15th, at the 4th China Automotive Quality Forum and the 2020 Auto User Satisfaction Evaluation Results CACSI Press Conference, BEIJING Automotive New Energy ranked No. 1 in after-sales service satisfaction for new energy vehicles for the sixth time.

At the 2020 final evaluation meeting of the “China Automotive Industry Science and Technology Award” held recently, the key technology and industrialization project of the BEIJING automotive three-electric platform won the first prize of the Science and Technology Progress Award. The expert group gave “The overall technical level of the project has reached the international advanced The evaluation opinion is that the driving range per kilowatt-hour, the vehicle energy recovery rate, and the efficiency of electric drive NEDC working conditions have reached the international leading level.”

03 Technology "old guns" set a new benchmark in the industry

In the early stage of the new energy vehicle market, both traditional car companies and new forces built cars, relying on policy dividends to achieve barbaric growth. Nowadays, the market is gradually returning to rationality. Many new energy car companies are "fleeing the casualties", and only a few car companies that have achieved independent technological innovation have truly reached the end.

The difference between a leader and a follower lies in innovation. The ability of independent innovation often determines the height of a car company, which is also the consistent insistence of BEIJING Automotive New Energy.

With the continuous improvement of the research and development level of BEIJING vehicles in the field of new energy, it has begun to be constrained by the relatively lagging capabilities and levels of test equipment. At that time, it was often necessary to go to test sites across the country to conduct multiple tests, which not only consumed time and effort, but also increased costs. At the same time, some equipment had limited capabilities, which affected the efficiency and effectiveness of the test.

For BEIJING cars, technological advancement is only the first step, and an authoritative test center is also needed to verify the reliability of the technology. On July 22, 2019, the BEIJING Automotive New Energy Test Center, which was built at a cost of 2.051 billion yuan, was officially opened. The test center can conduct test capabilities in six key core areas including batteries, motors, electronic control, intelligent network connection, lightweight, and vehicle applications. It is the new energy vehicle test verification platform with the most complete test functions in China.

With more than 550 sets of world-class test equipment, the test concept, test standards and test capabilities are all at the leading level in the industry

The test center has complete vehicle environment, NVH, EMC, structural durability and other testing capabilities, covering pure electric and hybrid testing capabilities, and can carry out vehicle high and low temperature performance, thermal management performance and other environmental testing requirements. In terms of drive system, it has full environmental performance and reliability testing capabilities covering motors, powertrains, and transmission systems, and fully meets the calibration and testing requirements of motors, drive systems, and control systems.

Drive system power level test platform passed the controller efficiency MAP test

In the battery system laboratory, there are three test areas for battery PACK, battery cells and modules, and battery safety. It has comprehensive test capabilities from batteries to PACKs, and has full environments such as battery temperature and humidity, vibration, altitude, and salt spray. The testing capabilities of power-off performance and durability are 100% covered by the national standard and enterprise standard test system.

The 16-ton three-combined vibration table can perform the vibration test of the battery pack

The battery PACK test area is constructed in accordance with the standards of German Mercedes-Benz, with a maximum discharge power of 550kw and a current measurement accuracy of three ten thousandths, which is an order of magnitude higher than the industry average level of one thousandth. Higher measurement accuracy means higher endurance accuracy, which is one of the important reasons why BEIJING cars can achieve excellent results in the WLTP evaluation.

In terms of intelligent networking, it includes laboratories such as intelligent driving, intelligent cockpit, and Internet of Vehicles testing, and has the ability to support the development of the open V2X interconnection platform and the research and development of intelligent networking. In the lightweight test zone, it has analysis and testing capabilities such as material analysis, microstructure defect analysis, etc., to provide support for the development of new platform lightweight components and car bodies.

V2X communication test equipment, function calibration and testing for V2X scenarios

According to the introduction of BEIJING automotive, the test objects can cover all fields and systems of electric vehicles, ranging from the solder joints for connecting components to the entire vehicle, including hardware and software. Yue Wei, director of the test department of BEIJING Automotive New Energy Engineering Research Institute, revealed that the test center's test mainly revolves around the three-electric system, the purpose is to prevent users from acting as guinea pigs under the rapid development of new energy vehicles.

In addition, the new energy test center will also be shared with the outside world and open to the entire industry. From the accumulation of vehicle three-electric technology to the ability to verify innovative technologies and applications, BEIJING Auto has gradually explored its own way.

Build and share with outstanding industry partners

Nowadays, the new energy vehicle market has entered the knockout stage, especially under the domestically-produced Tesla's destructive offensive, leaving little time for Chinese car companies. In this context, with more than ten years of technological accumulation, BEIJING Auto has continued to innovate and opened a leading domestic new energy vehicle test center to drive the progress of the entire industry and gradually establish a new benchmark in the domestic new energy vehicle field.

- Get link

- X

- Other Apps

Comments

Post a Comment